Oxidized Bitumen 115/15 – Premium Blown Bitumen Supplier

At Faragam Petro Tech, we manufacture and supply oxidized bitumen 115/15—a high-quality grade of blown bitumen produced by carefully heating and blowing air through refined petroleum bitumen. This process gives our product an exceptional flash point, softening point, and thermal stability, making it ideal for demanding industrial applications.

Why Choose Oxidized Bitumen 115/15

Oxidized bitumen 115/15 is valued for its durability, flexibility, and resistance to extreme temperatures. Thanks to its stable performance, it is widely used in:

-

Waterproofing and Insulation: Protect concrete surfaces in high-temperature areas by mixing with gasoline and spraying for long-lasting sealing.

-

Pipe Coatings: Provides corrosion protection and insulation for metal pipes.

-

Industrial Paints and Coatings: Enhances adhesion and weather resistance.

-

Floor Sealing and Construction: Creates durable, waterproof surfaces for commercial and industrial projects.

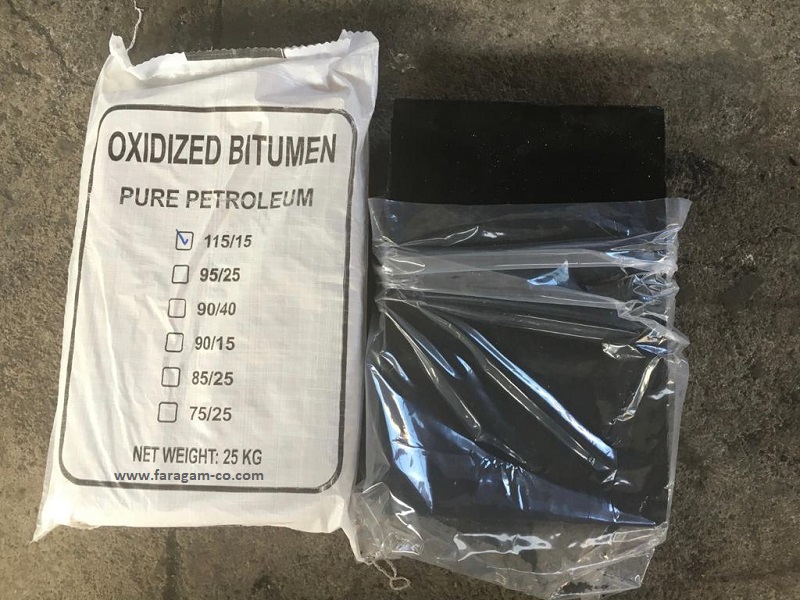

Packaging Options

To meet different project needs, Faragam Petro Tech supplies oxidized bitumen 115/15 in multiple packaging types:

-

25 kg paper or polypropylene (PP) bags

-

Durable craft sacks

-

Carton boxes (available upon request)

Global Supply and Export

As a trusted bitumen supplier, Faragam Petro Tech exports oxidized bitumen 115/15 to East Asia, Africa, China, CIS countries, and Europe. Our products are manufactured under strict quality control using premium raw materials and comply with ASTM standards, ensuring consistent performance for every shipment.

Your Reliable Bitumen Partner

With years of expertise in the petrochemical industry, Faragam Petro Tech is committed to providing reliable service, competitive pricing, and timely delivery. Whether you’re sourcing oxidized bitumen for waterproofing, insulation, or industrial coatings, we are here to support your business with dependable supply and technical guidance.

Analysis

| Bitumen 115/15 | Specification | Test method |

| Specific gravity @ 25/25 cg | 1.05 | D-70 |

| Penetration @ 25 c | 20/10 | D-5 |

| Softening point c | 110/120 | D-36 |

| Ductility @25 c | 1.5 min | D-113 |

| Loss on heating(wt) % | 0.2 Max | D-6 |

| Flash point c | 260 min | D-92 |

| Solubility is CS2(wt) % | 99 min | D-4 |